When choosing new wheels for your vehicle there are a couple of fundamental questions you should ask yourself first – do I want cast or forged wheels, and will one, two or even three piece wheels be best for my vehicle and how I use it?

With so many thousands of different wheel designs and styles out there to choose from, if you can answer those two questions you can dramatically speed up your search for the ideal set of wheels.

The Difference Between Cast and Forged Wheels

‘Cast’ and ‘forged’ refer to how the wheel was manufactured, which in turn will determine the wheel’s performance characteristics and its price. While price is always a factor but the performance capabilities of a wheel should also be taken into consideration.

A 1-piece cast wheel is removed

from the mould

To counter this manufacturers design cast wheels with greater tolerances, resulting in thicker, heavier wheels. However, cast wheels are generally cheaper than forged wheels due to the faster and less intensive manufacturing process.

Forged wheels are made from a solid block of alloy which is heated and subjected to immense pressure to create the wheel’s form and shape before it is finished on milling and CNC machines. This pressure generates an enormous amount of energy within the alloy which alters its molecular grain, giving it extreme strength. As a result forged wheels are far lighter (up to 30%) than cast wheels but have the same stiffness and structural integrity.

Making a forged wheel from

a single alloy billet

Cast wheels are generally cheaper than forged wheels due to the faster and less intensive manufacturing process. A cast wheel can be anywhere from 25% to 50% less in price than a forged wheel.

Which is Best: 1, 2 or 3-Piece Wheels?

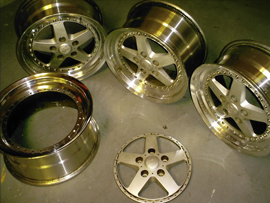

Multi-piece wheels can be disassembled

to repair damage. This is less expensive

than having to replace the entire wheel

Once you’ve decided whether you want cast or forged wheels, it’s time to choose between 1-piece, 2-piece or 3-piece wheels.All cast wheels are manufactured in a single piece of metal, or monobloc, so they are referred to as 1-piece wheels. Because of their added strength forged wheels can be manufactured as 1-piece, 2-piece, or 3-piece wheels.

A 2-piece wheel is made from a center piece complete with spokes and a rim section. This allows for more intricate designs and even the use of different materials in one wheel.

KMC Dime 2-piece wheel with the bolts

joining the two elements clearly visible

The 3-piece wheel follows the same construction principles but the rim is created from two separate halves. Now the manufacturers can create a far greater range of widths and offsets for a single wheel design. To create a different width/offset only requires that the front or back half of the rim be changed. There are far more offset, backspace and width options available with 3-piece wheels.

Damage control is another benefit of 2 or 3-piece wheels. The stronger forged material is more resilient against bumps and scrapes, but even if the wheel is damaged, repairs are usually cheaper because only the damaged wheel section need be replaced, not the whole wheel.

Okay, now you know how wheels are made, you are in a better position to buy the rims that will suit your driving style the best.

By John Bone

Posted on September 9th, 2013