Slick new KMC Slide Alloys on an F150

Something to bear in mind when fitting nice new wheels to your vehicle is how they attach to your prized ride. This is particularly true for anyone who will be taking their vehicle off road. Few things are more unpleasant than seeing one of your very expensive rims parting company with your truck, leaving you to paraphrase the old song “You picked a fine time to leave me loose wheel”.

Hub or Lug: The Two Ways to Fit Wheels

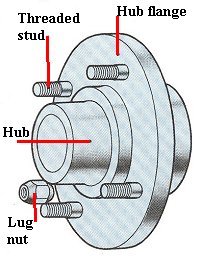

It all boils down to the way the wheel was manufactured and therefore attaches to the vehicle. This falls into two categories; hub-centric wheels and lug-centric wheels. With a hub-centric attachment the wheel mounts snugly over the wheel hubs, so the hub coupling supports the vehicle’s weight and the lug nuts simply connect the wheel to the hub. The lug-centric attachment uses the lug studs to both support the full weight of the vehicle and keep the wheel firmly attached.

Incorrectly mounted wheels

can lead to this…

Needless to say, the hub-centric attachment method is far superior to the lug-centric attachment because the hub centers the wheel and takes the majority of the mechanical forces traveling through the wheel/hub assembly.

The lug-centric method places a large strain on the lug studs which are dealing with the rotational movement of the wheel, the weight of the vehicle and all the additional forces such as bounce and yaw. Lug-centric wheels are also less likely to be perfectly centered, which adds even more mechanical stress to the lug studs as well as the wheel bearings.

Why do OEM and Aftermarket Wheels Differ?

OEM manufacturers can make a specific wheel for a specific vehicle, but the aftermarket wheel manufacturers don’t have this luxury. While OEM manufacturers can machine hub-centric wheels to high tolerances, aftermarket manufacturers have to adopt the lug centric route because it’s not known to which vehicle a wheel will be mounted. So that a wheel will fit the widest possible range of vehicles, the hub opening is bored wider than the hub and thus relies solely on the lug nuts to carry loads.

Helpful Tips When Fitting New Wheels

The wheel hub and lug stud mounting

points can be clearly seen here

To counteract the disadvantage of the lug-centric attachments required by many aftermarket rims, the professionals use certain tricks to ensure a wheel is perfectly centered and firmly attached.

Fitting hub-centric rings is cheap (less that $10 per wheel) and highly recommended. Made from extremely durable plastics or aluminum, the hub-centric ring seals the gap between wheel and hub, thus allowing load to be transferred through the hub and reducing the load on the lug studs. and making the wheel’s attachment more hub-centric. Hub-centric rings also help to center the wheels, eliminating shudder and improving the ride quality.

Hub-centric rings keep aftermarket

wheels centered and stable

Bear this in mind when adding wheel spacers or bolt pattern adapters. Make sure the wheel is never in contact with any threaded part of the studs.

The wheel/hub assembly encounters tremendous forces during stable highway use and when driving off-road these stresses are multiplied. If when fitting aftermarket wheels your ensure they are mounted as securely as possible, you will go on to enjoy thousands of miles of driving enjoyment.

By John Bone

Posted on September 19th, 2013